This page will be used to post progress updates of ongoing projects

that are being developed by Momus CNC. It will also be used to post

modifications and improvements to the machine design that have not

yet been incorporated into the current version of the assembly

manual.

Research and Development

© 2012 Momus CNC

We are currently working on a print head and

extruder that will bolt onto the standard Momus

CNC router, turning it into a 3d printer.

The Momus CNC router has a combination of qualities that make it well suited for use as a 3d printer. In particular, its mechanical resolution and high speed movement.

This design uses standalone electronics to control the nozzle and printbed temperatures. A PID controller modulates the temperature of a line-voltage cartridge heater that is embedded alongside the nozzle. The 4th axis of Mach3 will be used to control the extruder, which uses a small stepper motor.

The Momus CNC router has a combination of qualities that make it well suited for use as a 3d printer. In particular, its mechanical resolution and high speed movement.

This design uses standalone electronics to control the nozzle and printbed temperatures. A PID controller modulates the temperature of a line-voltage cartridge heater that is embedded alongside the nozzle. The 4th axis of Mach3 will be used to control the extruder, which uses a small stepper motor.

momus cnc 3d print head

The parts for the extruder and nozzle will be able

to be fabricated using the momus cnc router.

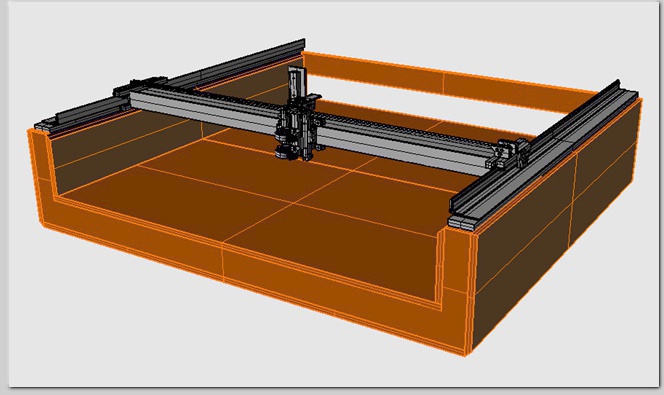

The design of the momus cnc router underwent

significant revisions between the first release of

the plans and the current version (2.0), which

was released in May 2012. Many of the changes

made to the design of version 2.0 were done

with the intent that the machine would be easier

to enlarge.

The rendering to the right is of an enlarged Momus CNC machine, with a travel of approximately 50" x 50". It will use a stepper motor drive on each end of the gantry axis, and these will be be slaved together through the control software.

The rendering to the right is of an enlarged Momus CNC machine, with a travel of approximately 50" x 50". It will use a stepper motor drive on each end of the gantry axis, and these will be be slaved together through the control software.

monster momus

While the enclosed design of the machine

effectively contains dust, it can still be beneficial

to equip the router with a vacuum dust collection

system. Numerous builders have already added

such systems to their machines.

dust collection system

Check back soon for updates...

The plans for this project will be released as free

open-source documents.